At the heart of uKonn-X is a software solution that uses customer data such as electrical PDF circuit diagrams, etc., to create a bill of materials (BOM). The software then generates a clear, interactive 2D/3D view of the assembly or the entire machine.

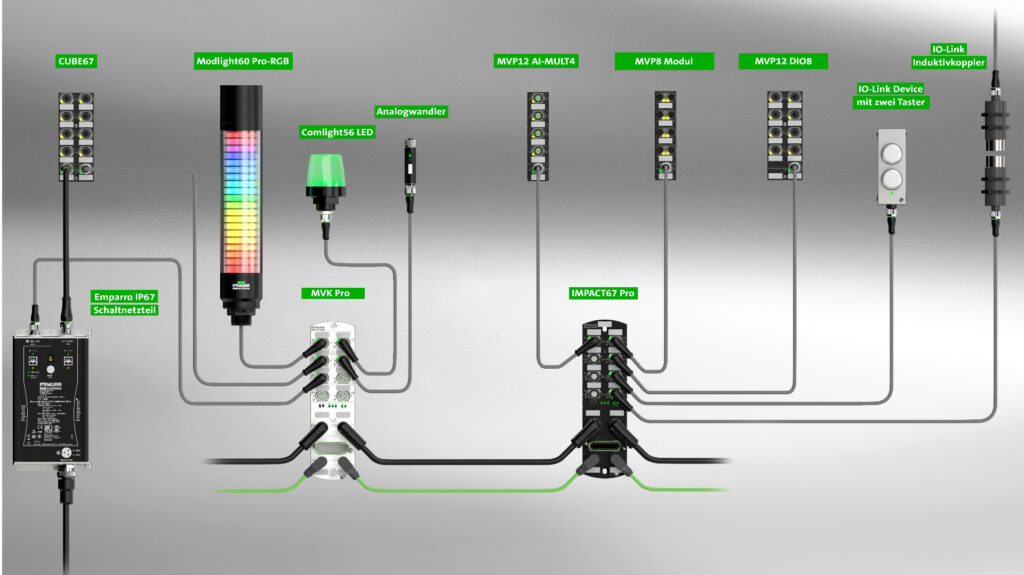

uKonn-X generates digital navigation maps, similar to Google Maps, where the BMK of the components used, such as sensors and actuators, fieldbus modules, and connectors, are the street names and house numbers. This system guides the user to their destination and allows them to see exactly where the electrical components are located and how they are correctly wired on their mobile device.

SCAN

Assembly department employees scan the components marked with QR codes using handheld scanners. Their positions are immediately displayed in the 2D layout view or in the 3D machine model.

INSTALLATION

The positioning of the components and the start and end points of the cable connections are visually highlighted. Even people who are unfamiliar with the location are guided intuitively and can reach the specified connection point without in-depth technical knowledge.

DOCUMENTATION

Once a task has been completed, the user confirms that the assembly has been carried out correctly, thereby triggering documentation in the program and enabling the next task in the assembly process to be carried out until completion. The production management team has live access to data on work progress and expected completion, as well as a readiness report.